As the paths for many pipeline projects traverse through more mountainous terrain, oil and gas companies are facing a number of challenges to maintain safe operations on increasingly steep slopes. To mitigate the risks that come along with operating heavy equipment on steep slopes, oil and gas companies need to develop plans that ensure safety for equipment operation, and handling and support of pipes and other components.

Today, there are some health and safety-focused organizations that do require companies working on steep slopes to have a written plan for tracked equipment. For example, WorkSafe BC in British Columbia requires written plans for work on slopes greater than 22 degrees. However, most oil and gas companies actually have tighter standards for requiring work plans to mitigate risk and increase predictability on site and protect employees, equipment, and the environment. Therefore, most of the time we are creating plans for slopes much less steep than 22 degrees.

Creating a steep slope work plan can be challenging since there is not a lot of industry-wide technical guidance or standards in place. However, our engineers at Allnorth have a lot of experience developing steep slope operation plans. Let’s look at some of the considerations we make when creating plans for steep slope engagements.

The Allnorth Process for Creating Steep Slope Engagement Plans

When we engage in a project with a steep slope, our first step is to determine what the client needs to accomplish and what equipment they plan to use onsite. We then perform a slope assessment with topo data provided by the contractor or client. Based on this assessment, we provide clients with site-specific drawings tailored to safely allow equipment and pipe on the slope. If requested, we can also create safe work plans for how work is to occur on the slope.

Considerations for Developing Steep Slope Construction Plans

While this process may sound simple at a high level, there are a lot of factors to look at when developing a steep slope construction plan. These factors include the operation of the equipment itself, the roads required to get equipment and workers safely up and down the slope, and the storage of debris and materials onsite. Let’s look at the key considerations for addressing the challenges associated with each of these factors.

Operating Heavy Equipment

There are a lot of variables to consider when working with heavy equipment on steep slopes. One of the more complex factors we look at is the traction coefficient of the equipment. If the equipment has a low traction coefficient it will not be able to gain traction as it is being winched up the slope when ice, snow, or loose materials are present, and this must be compensated for. If the equipment has a high traction coefficient, the power to the engine can be leveraged when going up the hill on better materials like densely packed soils.

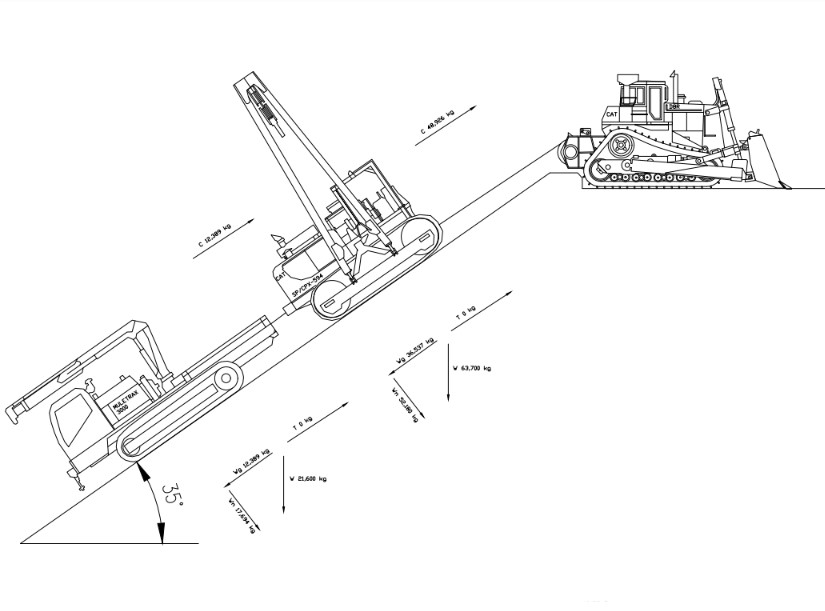

We also consider the need for rigging and anchorage for the equipment. This could be for a winch at the top of the slope or anchorage on the equipment itself. We determine what is needed by going onsite and performing measurements of all the tow and anchor points. We then design a plan for how the winch is anchored and specify the size of all wire rope, shackles, and rigging for the winching system for maximum loading (Figure 1). We can also provide a memo for what the lug, which is where ropes and shackles attach to the equipment, will be rated for.

Figure 1. An example of a winching diagram we provided for a client.

Figure 1. An example of a winching diagram we provided for a client.

Pipe Handling and Storage

To ensure that pipe is stable when it is on the slope and ensure that pipe is transported up and down the slope in the safest manner possible, we develop pipe steep supports and handling plans. There are two methods we use for proper pipe support – an upper restraining head or a lower restraining foot. The upper restraining head is a system that holds the top of a pipe section when it is on the slope. This design includes pipe connection detail, associated rigging, and winching limitations. A lower restraining foot is a support system at the bottom of the slope to hold the pipe on the slope. There are multiple design options we can use for this including a timber wall, soil backfill, or soil berms.

We can also design systems for pipe handling. This generally involves a plan to safely move pipe up the slope to the steep slope staging areas and ensure that pipe is stabilized on the construction equipment as it is transported.

Protect Your Employees and Assets with Prior Proper Planning

Properly planning for steep slope pipeline projects not only enhances safety but having a plan in place can oftentimes reduce construction timelines and costs as well. While there are no industry-wide standards in place for planning for the challenges associated with working on a steep slope, most oil and gas companies recognize that these challenges need to be addressed. Allnorth has many years of experience working in these environments and can help ensure you account for all the nuances of steep slope construction in your next project.

Technical content provided by Michael Darasz, P.Eng., Ryan Monsees, P.Eng., M.Eng., and Don Williams, P.Eng.

Learn more about the civil engineering services we offer from preliminary planning through construction completion.