Introduction: A Plan Towards Sustainable Mining

Gold has long held a significant place in human history, symbolizing wealth and prosperity. However, the production of gold is not without its challenges. In the modern era, emerging complexities are reshaping the gold mining landscape. Lower ore grades, increased impurities, and growing refractoriness all pose new hurdles for miners and metallurgists. Furthermore, stakeholders remain keen to see a quick return on their investments, placing additional pressure on metallurgists to design gold extraction processes that optimize both recovery and profitability. In this blog, we will explore the key steps in designing sustainable gold mining facilities, such as selecting the right extraction process, and in highlighting the expertise of Allnorth in providing a responsible approach to sustainability in gold flowsheet design.

Selecting the Right Extraction Process

Responsible gold mining principles do not have to come at the sacrifice of other important factors.

A metallurgist's primary role is to develop a robust, flexible, and optimized process flowsheet that aligns the metallurgical performance goals with the commercial objectives of the project. Working closely with project owners, metallurgists help to establish the mine production rate, define achievable recovery targets, and select an extraction process that ensures manageability, sustainability, and profitability. A successful flowsheet strikes a balance between processing rate, gold recovery, product quality, technical risk, and commercial profitability. Responsible mining companies incorporate all these considerations and factor in how to best recoup value for their investors sustainably over the life of mine.

Considerations and Pitfalls

Regrettably, some mining operations fail to adequately consider the financial impact of their metallurgical designs. Processing rates may be set too low due to capital limitations or too high based solely on economic scale. The focus may lean towards maximizing recovery or minimizing capital expenditure, thus disregarding operating cost implications and technological limitations. Inexperienced metallurgists may display a bias towards a specific technology, inadvertently excluding potentially more suitable yet unfamiliar processes. In recent times, projects following a "copy-and-paste" approach have emerged, sacrificing design work for accelerated delivery times but introducing excessive technical risks.

At Allnorth, we understand that profitability is the ultimate goal. To confidently provide a sustainable, reliable return on investment, Allnorth will not entertain biases towards select technology or scale an operation irresponsibly. The profitability of the operation must be sustainable throughout its life of mine. This includes future expansions, possible modernizations, and even extension of the life of the mine itself.

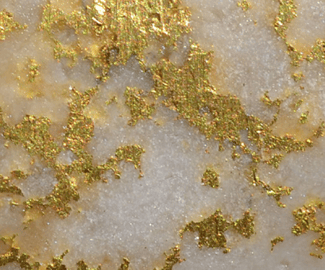

Embracing Orebody Uniqueness

Each gold orebody is unique, akin to a fingerprint, and requires careful evaluation. Factors such as composition, mineralogy, hardness, impurity profile, and chemical reactivity can all vary widely. Additionally, geographical location, orebody depth, site accessibility, skilled operating requirements, power availability, consumable requirements, water quality, and changing climate patterns all contribute to the intricate considerations for optimal gold process design. It is also an essential requirement to understand in detail the variability of an orebody's unique ore characteristics and their variability over the life of the mine (LOM).

At Allnorth, we begin our design criteria with the location of the orebody itself - the one factor that can never be changed. We design each gold extraction process to always consider the unique requirements of the orebody location. Climate, seasonal impacts, logistic barriers, local regulations, energy and water security, waste management, language, local culture, and even community approvals are just some of the items we consider in our design from day one. Each orebody is unique, so each design criteria must also be unique.

The Bespoke Nature of Gold Process Design

Designing an efficient gold process is a bespoke exercise that encompasses multiple factors. At Allnorth, we simplify the fundamentals to help our clients navigate the complexity of the design process. In almost all cases, it begins with a comprehensive baseline test work program to determine the extraction process and scale that offers the best economic value. Maximizing scale and recovery do not always translate to increased profit. Finding the optimal balance point minimizes operating costs and technical risks while maximizing production and quality, resulting in sustainable and profitable operations.

At Allnorth, helping our clients achieve their profitability goals is of utmost importance to us. Minimizing operating expenditure is therefore equally as important as the original capital requirement. Maximizing profit allows our clients to pay down the debt quickly. It promotes larger and faster shareholder income. And it allows our clients to reinvest in their assets for greater value.

Allnorth: Your Partner in Responsible Gold Mining Principles and Project Management

At Allnorth, we understand the critical importance of responsible gold project management. We approach each process design meticulously, ensuring it aligns with our strict evaluation criteria. Our expert team designs process plants that strike the right balance between recovery, technical risk, reliability, and commercial benefit. The outcome is a gold operation that can sustain its nameplate production rate and profit margin over the entire life of the mine.

At Allnorth, we understand the critical importance of responsible gold project management. We approach each process design meticulously, ensuring it aligns with our strict evaluation criteria. Our expert team designs process plants that strike the right balance between recovery, technical risk, reliability, and commercial benefit. The outcome is a gold operation that can sustain its nameplate production rate and profit margin over the entire life of the mine.

Conclusion

The realm of gold mining is continuously evolving, presenting new challenges and opportunities. By selecting the right extraction process, considering orebody uniqueness, and prioritizing sustainable profitability, mining operations can thrive in this dynamic landscape. Allnorth's expertise in responsible gold flowsheet design and our commitment to maximizing profitability make us the ideal partner for your gold project. Trust Allnorth to deliver innovative, customized solutions that optimize your gold operation for long-term success.

The realm of gold mining is continuously evolving, presenting new challenges and opportunities. By selecting the right extraction process, considering orebody uniqueness, and prioritizing sustainable profitability, mining operations can thrive in this dynamic landscape. Allnorth's expertise in responsible gold flowsheet design and our commitment to maximizing profitability make us the ideal partner for your gold project. Trust Allnorth to deliver innovative, customized solutions that optimize your gold operation for long-term success.

Our team of experienced professionals is ready to provide a tailored solution to maximize the efficiency and profitability of your gold operations. Don't miss out on the opportunity to optimize your gold operation with Allnorth's comprehensive expertise and commitment to creating financially responsible and sustainable mining practices.

Learn More

For more information about Allnorth's expertise in responsible gold flowsheet design and how we can support your gold project, please download our whitepaper, The Fundamentals of Responsible Gold Flowsheet Design.

Contact us today to discuss your project requirements and let us help you achieve sustainable success in the gold mining industry.

.png)

.png)